The Aluminum Composite Inner Bag: Tough, Durable & Recyclable

Under the "dual-carbon" strategy, Shanghai Tangke New Materials focuses onaluminum composite inner bags for ton bags. Via technological innovation, it has developed products with both protective and eco-friendly features, offering a new solution for the industry’s green transformation.

Innovative Material System

The product uses a 4-layer PET/AL/PA/PE composite structure, with each layer complementing the others: PET ensures structural stability, aluminum foil forms a tight barrier, PA boosts material toughness, and PE guarantees sealing performance. Precise material proportioning and functional integration not only meet protection needs but also lay the foundation for efficient resource use.

Optimized Structural Design

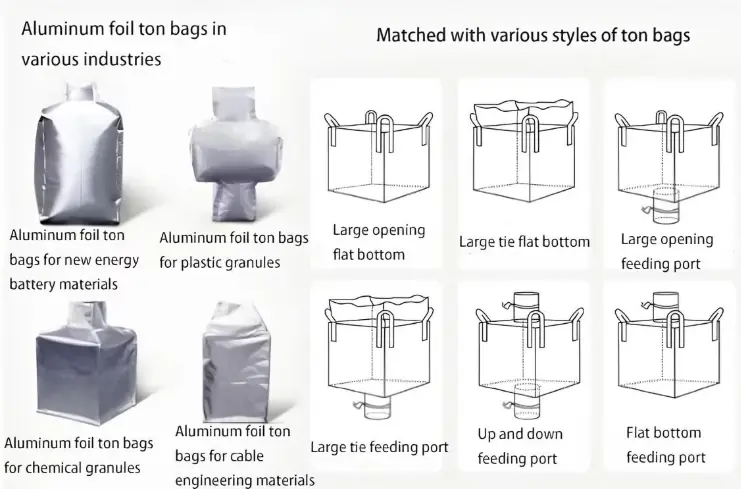

Through scientific thickness control and diverse bag designs (circular, square, U-shaped), the product balances performance and environmental protection. It fits loading scenarios in chemical, new energy, pharmaceutical and other industries—improving operational efficiency, reducing risks, and avoiding resource waste from poor adaptability.

Focus on Circular Environmental Practices

To meet the ton bag industry’s demand for carbon and waste reduction, the company enhances the eco-friendliness of its aluminum composite inner bags: optimizing material ratios to cut primary resource use, and focusing on the full-life-cycle environmental impact of composite materials. Multi-dimensional measures reduce packaging’s environmental footprint, supporting the industry’s circular economy.

In the future, Shanghai Tangke will continue to deepen material innovation and eco-tech R&D, refine products and services, and contribute to the sustainable development of the ton bag industry.