Shanghai Tangke New Material Technology Co., Ltd.'s representative product ——Nylon Co-extruded Film

Since its establishment in 2006, Shanghai Tangke New Material Technology Co., Ltd. has been committed to customizing various green, healthy and safe functionalpackaging films for customers. The company is located in Jinshan District, Shanghai, with an investment of 350 million yuan in the first phase, covering an area of more than 60 acres, with a total construction area of 60,000 square meters. After years of development, it has built complete product supporting facilities covering blown film, printing, lamination, slitting, bag making, etc., with an annual output of more than 50,000 tons of nylon co-extruded film and aluminum-plastic composite film.

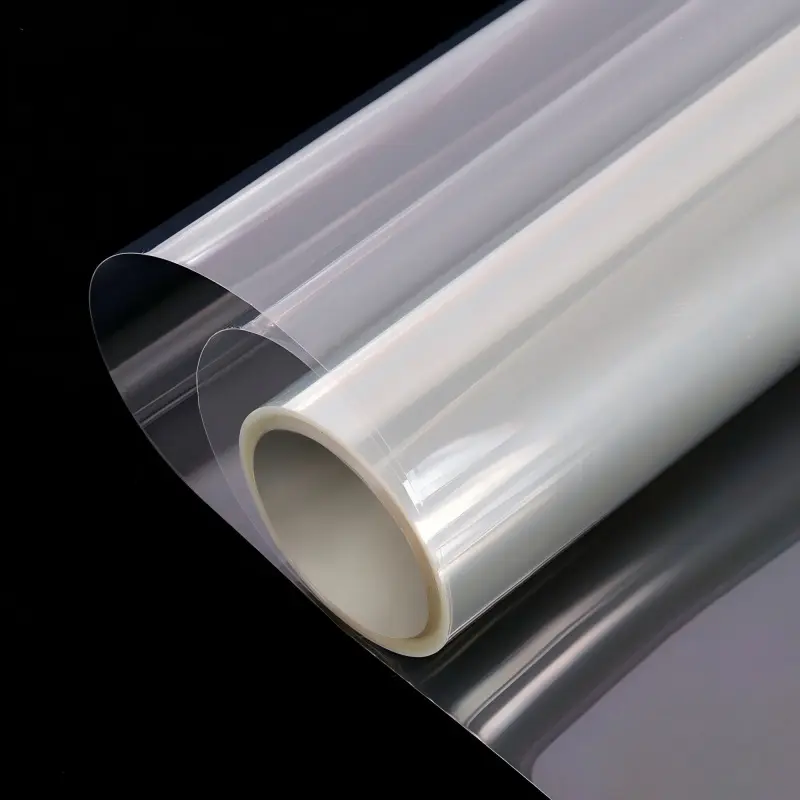

Tangke's nylon co-extruded membrane has a variety of different structures and specifications to meet diverse application needs. Among them, common structures such as PE/PA/PE, the regular specification is 45/50/60um. This structural design gives unique advantages through nylon raw materials, significantly increasing the fullness of the air column and making it less prone to rupture. In the process of logistics and transportation, it can better protect the contents and effectively reduce the risk of damage, so it is widely used in glass products, toner cartridges, fruits and other fields with high requirements for packaging protection. Taking glass product packaging as an example, glass products are very easy to be damaged by collision during transportation, and Tangke's nylon co-extruded film greatly reduces the crushing rate of glass products with excellent toughness and air column support, and reduces transportation loss costs for enterprises.

The other is a nylon co-extruded film with PA/PE, PA/EVOH/PE structure, with regular specifications of 70/95/125um. By adding the barrier materials PA and EVOH, the product has excellent waterproof, moisture and gas barrier properties. In food, pharmaceutical and other industries, product deterioration is often closely related to moisture and oxygen in the external environment. Tangke's nylon co-extruded film can provide a reliable barrier for the product to prevent it from deteriorating due to moisture, oxidation and other factors, thereby effectively extending the shelf life of the product. In terms of food packaging, for some dry goods, snacks and other products, the shelf life can be extended several times after using this nylon co-extruded film packaging to ensure that consumers can enjoy fresh and delicious food for a long time.

There are also nylon co-extruded membranes with structures of PA/PE (PP), PA/EVOH/PE(PP), and regular specifications of 140/180/200um, which are made by advanced downblow water cooling process. It not only has excellent airtight barrier performance, but also can meet the needs of content preservation, anti-oxidation, moisture-proof, puncture resistance, high-temperature sterilization, anti-film surface curling and other needs, but also has good heat sealing strength and thermal viscosity effect. This feature ensures that the packaging will not break after sterilization, greatly improving the stability and reliability of product packaging. At the same time, the film surface presents a high transparency and high gloss appearance, which can be used for printing and visualization, and can adapt to the requirements of high-speed automatic packaging of Vacuum continuous automatic packaging machine, which greatly saves the labor cost of the packaging link. In the pharmaceutical industry, the packaging of drugs needs to strictly meet hygiene standards and have good barrier properties, and Tangke's nylon co-extruded film fully meets these requirements, providing a strong guarantee for the safe storage and transportation of drugs.

Tangke can produce such high-quality nylon co-extruded film without its advanced production equipment. The company introduced the world's advanced German W&H nine-layer co-extruded high-barrier film blowing equipment, which adopts a fully modular design. The equipment is equipped with a weighing ratio and particle flow adjustment device to ensure the accurate ratio of raw materials and ensure the stability of product quality from the source. The precise design of the blown film die makes the film molding more uniform; The internal cooling device of the film and the rotary traction device cooperate with each other to further optimize the physical properties of the film. The film width and thickness measurement and adjustment device ensures a small film thickness deviation, so that the scrap rate after the equipment is started is reduced to a low level, and at the same time, the film is of stable high quality. In addition, Tangke Company uses raw materials that have passed international authoritative certifications such as FDA, EC, REACH, etc. in the production process, and does not add any additives that affect product safety during the processing process, which fully ensures the application of products in food, medicine, electronics and other packaging fields with high safety requirements.